PRODUCTS AND SERVICES

ADDITIONAL PRODUCTS / SERVICES

OUR TECHNOLOGY

FEATURES ADVANTAGES BENEFITS

TESTIMONIALS

BACKGROUND AND HISTORY

|

CONTACT PRODUCTS AND SERVICES ADDITIONAL PRODUCTS / SERVICES |

OEM

INFORMATION OUR TECHNOLOGY FEATURES ADVANTAGES BENEFITS |

US ENCLOSURE DESIGN STUDIO TESTIMONIALS BACKGROUND AND HISTORY |

|

4" diameter ( .02 cubic foot ) to 36" diameter ( 12.9 cubic feet ) capability to manufacture to 240" diameter *20 foot* ( 4190 cubic feet ) |

| Major Achievements: |

| • Boeing avionics radar dome design. |

| • Circus Circus Hotel and Casino, 80 custom-designed spherical loudspeaker enclosures for large venue in Reno, Nevada. |

| • Cirque du Soleil, design for PA application. |

| •

Columbia University / Princeton University,

innovative multi-driver 360 degree field design in a

14-inch spherical 720 watt monitor/PA-- called

" Acoustahedrons " |

| • Ericsson (of Sweden) loudspeaker enclosure for anechoic sound chamber calibration. |

| • US Government contracted US Enclosure for products for Military efforts against Terrorist Attacks. |

| •

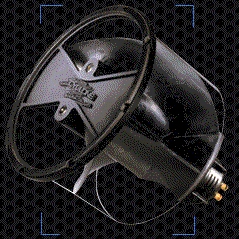

Designer and Manufacturer of the Largest spherical

loudspeaker enclosures. We manufactured 36"

diameter carbon-fiber braced spherical loudspeaker

enclosures-- our competitors largest is just 12" and made of aluminum... ( our largest product is 24 times the volume, 3 times larger in diameter ); and a capability to go to 96" diameter for Sound Reinforcement applications. |

| •

Largest egg-shaped loudspeaker enclosures ever sold.

These enclosures are the only ones of this shape that

are engineered with no internal diffraction as a

specific element for better sound quality. Other companies have used the shape for tweeters and only applied the exterior shape for sound quality improvements. |

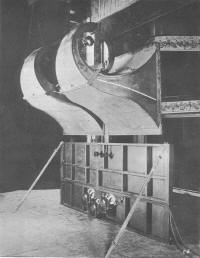

| • Only Wing-Shaped Parabolic loudspeaker enclosures ever built, which are ALSO the only floor standing (Curved) parabolic shaped loudspeakers ever built ( 30" tall ). |

| • Levitated Composite Core loudspeaker stuffing system devised by US Enclosure Company. |

| • Super-Stuffing 10 times as sound absorbent as any loudspeaker stuffing material currently on the market. |

| • Spherical D'Appolito configuration (MTM) utilizing ribbon tweeters. |

| •

ONLY COMPANY that engineered & developed to

market a FULL-LINE of Curved Cabinet Loudspeaker

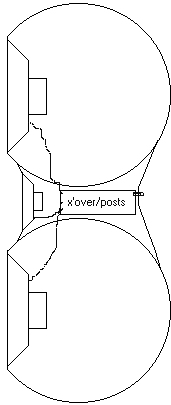

Enclosures; Subwoofers to 25hz -3 db; Complete THX

Compliant Home-Theater systems; A Full/Wide Range line of speakers; all using our enclosure materials and designs. Example, we began manufacturing bi-polar (di-pole) Rear- Channel spherical speakers in 1997 to accommodate the unique demands of THX home theater. |

| Aureal Semiconductor | Babb Loudspeaker | Boeing | Checkpoint Systems | Circus Circus Hotel and Casino | Cirque du Soleil |

| Claremont Colleges | Columbia University | Delta State University | Dolby Laboratories | Ericsson Cell Phone Manufacturing | Firewire |

| Fisher Scientific International | Instrumental Media | Lightware | Michigan State University | NASA ( United Space Alliance ) | Prairie Logic |

| Princeton University | Ramtel Communications | Saitama Medical School ( Japan ) | San Diego State University | Sound Alignment Systems | Sound Advance |

| University of California Davis | University of Massachusetts | ||||

| One of our

strong points is our utilization of acoustic

principals in loudspeaker enclosure materials and design

principals. Our best known design products are

loudspeaker enclosures with a shape which reduces

acoustic diffraction effects compared to all common box

shaped loudspeaker enclosures We have taken this

design/shape concept to a new level of

manufacturability... walls equal to or better

acoustically than any wood based

enclosure. We have the unique combination of customer experience and service, curved cabinet manufacturing and design expertise, and curved-cabinet manufacturing experience Our acoustically improved and visually appealing cabinets fit in any environment... home, professional media production facility, or concert hall. OEM Loudspeaker Manufacturers cabinets can be refreshed as a design improvement for existing lines or for a completely new product line. The designs are then eye-pleasing and consumer acceptable. They also reduce cone bleed-through and exterior diffraction which improves your products sound. Finally, we specialize in loudspeaker cabinets, yet, our technology lends itself to a wide variety of other applications involving wave energy-- from optical integrator spheres to industrial containment vessels. |

|

|

Company History

|

OVERVIEW |

| 1992: Multimodulus Cabinet material developed | 1994: US Enclosure Company organized |

| 1995: Website launched | 1997:

Loudspeaker line developed |

| 2000: Our

products subject of paper presented in Berlin, Germany

by professors from Columbia and Princeton Universities |

2005: Constrained Boundary Layer Multimodulus ( CBM ) developed |

| 2010: D. S. Ragsdale is asked to become full partner and accepts | 2011: Harmonic Dampening Material developed |

| 1990: |

This year US Enclosure Company Begins when Kris Metaverso reviews articles written by Dr. Henry Olsen on non-diffracting loudspeaker shapes at a College Engineering Library. Intrigued, Metaverso builds a number of spherical loudspeaker cabinets. |

|

Metaverso

tests confirm that all spherical-shaped loudspeaker

enclosures have unique resonance's inside the curved walls. Engineering-work begins for special

dampening of spherical sound waves which lead him away

from standard loudspeaker stuffing to a focus on (A) finding the truly-proper Enclosure Wall Materials specifically designed to absorb the energy inside a loudspeaker enclosure for (B) any loudspeaker cabinet shape to be (C) mass-manufactured. |

| Multi-Modulus is

the loudspeaker enclosure wall material developed from

this research and, in August 1992, fully perfected for loudspeaker cabinet mass production. |

|

| First multi-modulus test-enclosures produced for acoustic test purposes. | |

| Ultimate Speaker

Enclosure Company originates, shortened in 1995 to US Enclosure

Company. |

|

| 1991: | |

Metaverso incorporates Levitated Composite Core technology inside spherical loudspeaker enclosures to defeat the standing waves inside curved loudspeaker enclosures. |

|

1992: |

Brian O'Neill

begins to use the Pre-WWW Internet to market a product

he manufactured and marketed since 1989. Previous to the Internet marketing experience, O’Neill originally used 10 nationally distributed specialty periodicals to market his product called a "Sock Monkey" doll for babies. The motion picture Cabin Boy featured his product in one scene. O'Neill's “Sock Monkey” was also featured on ABC-TV's Home Show in 1992. Company Name: The Marketing Tide. |

|

Metaverso tests multi-modulus loudspeaker enclosures for mass-manufactured designs. The first multi-modulus loudspeaker enclosure with a multi-driver configuration produced with each driver having it's own curved enclosure within the main curved enclosure body. This cabinet also used Levitated Composite Core stuffing technology and techniques. |

| 1994: | |

|

Metaverso and O’Neill meet. O’Neill applies his experience with advertising, marketing & sales to Metaverso's loudspeaker cabinet innovations and US Enclosure Company organizes. First multi-driver multi-modulus spherical curved enclosure designed, manufactured and sold to third-parties. |

| 1995: | |

|

US Enclosure

Website launched. Original site

completely Hand Coded by Kris Metaverso without web

editing software and was located at http://www.aol.com/kmetaverso. US Enclosure has a 20 Year permanent web and internet presence. 36" pair of Spherical Loudspeaker enclosures for JBL 18" woofers designed by Metaverso, then manufactured and shipped to a client in Michigan. The Largest curved loudspeaker enclosures ever commercially produced. |

| 1996: | |

|

Egg-Shaped

Loudspeaker Enclosures perfected and placed into the

marketing/manufacturing-mix. US Enclosure MARK SERIES egg, sphere, and wing shaped loudspeaker designs prototyped and tested . |

| 1997: | |

|

US Enclosure MARK

SERIES is publicly unveiled and offered to the

consumer with 12 different loudspeaker models from: * Two Center-Channel models including a Dual-sphere Center Channel. * Two Subwoofer models including a 25Hz f3 Subwoofer actively correctable to 20Hz f3. * Three Rear-Channel models and a side-channel model ... 4-way gimbal-adjustable Dipole w/rear-firing ribbons. * Four completely different Front Main Speakers in 2 and 3 driver configurations including ported and sealed spherical, egg-shaped and wing-shaped units. Floor standing, Bookshelf, and a unique ceiling hanging 2 and 3 way Front Mains using spherical or egg-shaped cabinets. All UNITS ARE THX-Compliant. |

1998: |

Floor Standing Curved Wing-Shaped Loudspeaker Enclosures developed housing a 3-way loudspeaker system. Sound quality is lab-tested and compares much better compared to the original box-enclosed loudspeakers from which the drivers were derived. These are the Worlds first Floor-Standing multi-driver spherical enclosure loudspeakers and are designed to compete with standard floor standing loudspeakers. World's first spherical enclosures with egg-shaped interiors. 80 unit production order for Circus Circus Casino delivered. |

| 1999: |

|

|

US Enclosure

moves to a 1400 sq. ft. facility at 1495 W 9th Street

#306, Upland, CA. US Enclosure designs, engineers, manufacturers and delivers 30" spherical loudspeaker enclosures with three vari-vent ports driven by Phoenix Gold vane-based subwoofer Drivers per the ContraBass concept. |

| 2000: | |

|

US Enclosure

subject of paper presented in Berlin, Germany at the

2000 International Computer Music Conference. |

| 2003: | |

|

US Enclosure has

by this date completed over 300 CUSTOM Curved

multi-modulus based loudspeaker enclosure projects for companies. US Enclosure refutes further Non-OEM work. Full-scale Test Manufacturing for OEM clients occurring. |

2005: |

Constrained Boundary Layer Multimodulus CBM Loudspeaker Cabinets available for mass manufacturing. |

2006: |

US Enclosure achieves 343 custom enclosure design projects with concurrent manufacturing. |

2007:  |

US Enclosure creates it's Design Studio after realizing US has unique experience developing groundbreaking loudspeaker cabinet designs and manufacturing them for our clients. |

| 2010: |

D. S.Ragsdale is asked to become and accepts full 3rd partner, allowing US Enclosure to absolutely become the world leader in curved loudspeaker cabinet manufacturing for OEM's. Ragsdale has 15 years’ experience in operations management using our manufacturing method. Ironically, Devin's father Michael has 40 years’ experience working with companies including engineering for JBL. |

|

2011:

|

Harmonic Dampening Wall Material Developed. Comprehensive curved shape cabinet library completed for OEM Paid Client Reference. Every curved shape usable for loudspeaker cabinets is in this library with loudspeaker applications detailed with drawings. From sphere, egg, and hyperbolic ellipsoid parabolic, to Witch of Agnesi and Alexander Horned Sphere and in the middle Focaloid, Klein Bottle, Oloid, Hippopede (capsule shape), we have over 100 quality shapes in this library and all non-loudspeaker cabinet utilized shapes are now legally protected as loudspeaker cabinet shapes by publication. Our clients have protected shapes at their disposal. We can mass manufacture all shapes in our library. |

|

2012:

|

Turntable Plinth, Chassis and Housing Manufacturing using our MultiModulus at 130 pound per cubic foot or higher. |

|

2013:  |

These Are Loudspeakers Design Concept. |

2014:  | Chord and Cradle ADJUSTABLE HORIZONTAL AND VERTICAL CABINET DIRECTION Concert Enclosures and Rigging Systems Produced Final full scale design prototype for new World Trade Center NYC 82nd floor Music Conservatory 2016 |

| 2017: | World Trade Center Custom Cabinet Project at 30 Park Place / Four Seasons |

THE FUTURE is NOW:  |